European industrial projects face intensifying pressure from skilled labor shortages, threatening project timelines and quality standards. Strategic pipe fitter recruitment Vietnam has emerged as a reliable solution, providing European engineering, procurement, and construction (EPC) firms with certified, audit-ready talent. This guide explores the operational excellence behind Vietnamese pipe fitting teams and why they deliver sustainable value across Europe’s energy, shipbuilding, and infrastructure sectors. For comprehensive procedural details, explore our complete Vietnam–EU welding & recruitment guide.

What Makes Pipe Fitter Recruitment Vietnam Reliable for EU Projects?

Fit-up Accuracy & Isometric Drawing Literacy

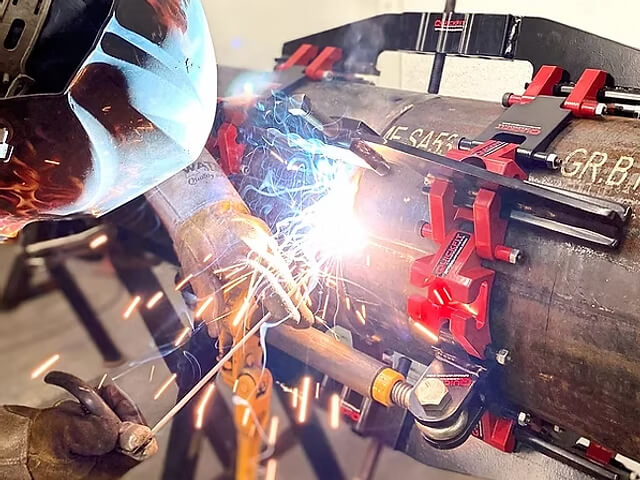

Vietnamese pipe fitters demonstrate exceptional proficiency in interpreting complex isometric drawings and P&IDs (Piping and Instrumentation Diagrams), ensuring precise component alignment before welding begins. This foundational skill in skilled labor Vietnam directly translates to reduced rework and enhanced first-pass weld acceptance rates. Meticulous attention to flange alignment, spool fit-up, and tolerance control – often achieving precision within 1-2 millimeters – establishes the quality foundation that European project managers require for complex installations.

Coordination with Welders & QA Teams

European EPCs repeatedly highlight the productivity gain when fitters and welders arrive as one synchronized unit. With shared drawings, hold points, and material control, teams move from fit-up to NDT with fewer delays. This is where pipe fitter recruitment Vietnam stands out: bilingual supervisors align task lists with welding leads at the start of each shift, protecting critical paths and reducing punch items. The effect shows in fewer reworks, smoother hydrotest preparation, and faster system turnovers across shipyards and process plants.

The synergy between Vietnamese pipe fitters and Vietnam welders creates seamless workflow integration that significantly elevates project efficiency. Through standardized communication protocols and shared understanding of quality benchmarks, these teams minimize interface errors during critical path activities. This collaborative approach, cultivated through joint training simulations, ensures that fit-up preparations consistently meet the stringent requirements of subsequent welding and non-destructive testing phases, creating a cohesive workflow that European quality auditors appreciate.

30–60 Day Mobilization Windows

Structured recruitment pipelines enable remarkably predictable 30–60 day deployment timelines from initial skills verification to on-site productivity. This operational efficiency – encompassing rigorous screening, documentation processing, and pre-departure orientation – provides crucial schedule certainty for European plant turnarounds and project commissioning. The ability to rapidly deploy certified teams during critical outage windows protects project timelines against costly delays, making pipe fitter recruitment Vietnam a strategic advantage for time-sensitive industrial operations.

When shutdown calendars are fixed, predictability beats everything. Through pre-vetting, visa know-how, and logistics coordination, pipe fitter recruitment Vietnam delivers a dependable 30–60 day ramp. That window allows planners to lock scaffolding, lifting, and inspection resources early, keeping workfronts open. For clients, this consistency translates to higher week-over-week spool completions and fewer idle crews standing by for materials or permits.

Compliance & Safety: Making Pipe Fitter Recruitment Vietnam Audit-Ready

Document Discipline: WMS, Permits, GDPR-Secure Records

Audit-ready documentation is not a slogan; it is a workflow. Mature providers of pipe fitter recruitment Vietnam maintain encrypted archives for qualifications, inductions, and toolbox attendance. Clients receive a tidy pack: cert scans, medicals, insurance proofs, and WMS references mapped to isometrics. That traceability reduces downtime during inspections and shortens sign-off cycles when QA teams verify personnel against permit-to-work systems.

Vietnamese recruitment partners have implemented comprehensive document management systems that ensure full compliance with European regulatory frameworks. The handover package for European clients typically includes verified welding procedure specifications, personnel qualification records, equipment certifications, and GDPR-compliant data processing agreements. This meticulous approach to documentation – often featuring digital archives with encrypted transfer – creates fully auditable trails that satisfy the strictest client and regulatory requirements for overseas welding jobs.

EU Site Safety Culture & Toolbox Talks

Vietnamese pipe fitters arrive prepared for European safety protocols through intensive pre-departure training that emphasizes site-specific hazard awareness and procedural compliance. This preparation includes comprehensive orientation on confined space entry protocols, hot work permit systems, fall protection requirements, and emergency response procedures. Regular safety briefings conducted in both Vietnamese and English ensure clear understanding of daily work instructions and hazard communications, facilitating seamless integration into multinational project teams.

Insurance & Welfare That Pass Client Audits

Reputable pipe fitter recruitment Vietnam partners verify comprehensive insurance coverage – including health, accident, and liability protection – that meets or exceeds European standards. Combined with pre-arrival accommodation inspections and ongoing welfare monitoring, these measures demonstrate genuine commitment to workforce well-being. This ethical approach not only satisfies corporate social responsibility audits but directly contributes to higher retention rates and sustained productivity throughout project lifecycles.

For additional information on European labor mobility frameworks, consult the official EURES – EU labour mobility information portal.

ROI Levers from Pipe Fitter Recruitment Vietnam

TCO Drivers: Rework Reduction & Onboarding Speed

The precision of Vietnamese skilled labor Vietnam in pipe fitting directly impacts Total Cost of Ownership through significant rework reduction and accelerated productivity ramp-up. Their expertise in first-time-accurate fit-up minimizes subsequent weld repairs and associated non-destructive testing costs. Combined with structured onboarding that typically achieves full productivity within 1-2 weeks, this precision delivers substantial cost savings beyond apparent wage differentials, creating compelling financial justification for European engineering firms.

Schedule Certainty for TAR/Turnaround Windows

Turnarounds fail when staffing fluctuates. With pipe fitter recruitment Vietnam, crews are assembled to mirror your shift pattern and priority systems. Supervisors submit weekly look-ahead plans referencing spools, supports, and tie-ins, so welding, NDT, and scaffolding resources stay in lock-step. This removes the classic bottlenecks—waiting for drawings, permits, or materials—and keeps hydrotest targets intact.

The predictable deployment of certified Vietnamese pipe fitting crews provides crucial schedule protection during planned plant turnarounds and maintenance outages. With mobilization timelines consistently within 30-60 days, European asset managers can confidently plan critical path activities without staffing-related delays. This reliability – particularly valuable during seasonal maintenance windows – enables earlier return-to-service for high-value assets, generating substantial operational cost savings and revenue protection.

Quality KPIs: Dimensional Checks, Hydrotest Readiness

Vietnamese pipe fitters deliver measurable quality outcomes through systematic dimensional verification and spool traceability protocols. Their meticulous approach to fit-up accuracy directly contributes to higher first-time hydrotest success rates – a critical quality indicator for European commissioning teams. Documented punch-list closure rates typically exceeding 95% demonstrate the direct correlation between skilled preparation and streamlined project completion, providing quantitative evidence of value delivery.

Where pipe fitter recruitment Vietnam delivers the most value in Europe

Shipbuilding & Offshore Modules

Vietnamese pipe fitters excel in complex marine environments, demonstrating specialized expertise in module fabrication, pipe rack assembly, and structural block integration. Their experience with diverse materials – including carbon steel, stainless steel, and corrosion-resistant alloys – aligns perfectly with classification society requirements for new construction and conversion projects. Proficiency in navigating tight spaces and adhering to stringent dimensional tolerances makes them particularly valuable for offshore platform construction and shipyard operations.

Energy & Process Plants

The energy sector – including power generation, oil and gas, and chemical processing – benefits significantly from Vietnamese pipe fitting capabilities across the project lifecycle. From prefabrication yard operations to field erection, these professionals demonstrate systematic understanding of pipe classes, pressure ratings, and material specifications. Their adaptability to both greenfield and brownfield environments, combined with rigorous safety consciousness, enables seamless integration into multidisciplinary project teams executing complex process installations.

Food & Pharma Utilities

Hygienic utilities require process discipline. Teams supplied via pipe fitter recruitment Vietnam arrive trained on surface finishes, passivation steps, and documentation etiquette common in GMP environments. They coordinate clean-area logistics, protect materials from contamination, and understand orbital weld hand-offs. For European food and pharma owners, that reduces deviation reports and speeds validation.

Vietnamese pipe fitters bring crucial expertise to hygienic process industries through specialized training in clean utility systems and high-purity piping. Their understanding of orbital welding interfaces, surface finish requirements, and Good Manufacturing Practice (GMP) awareness ensures compliance with stringent pharmaceutical and food processing standards. This specialized capability, combined with the precision of accompanying Vietnam welders for stainless steel tie-ins, positions them as valuable contributors to sensitive process environments where quality failures carry significant consequences.

Choosing the Right Partner for Pipe Fitter Recruitment Vietnam

Due Diligence Signals

Selecting a reputable recruitment partner requires verification of several critical capabilities beyond basic licensing. Essential due diligence should confirm valid MOLISA authorization from the Vietnamese government, in-house training facilities with European-standard equipment, and documented reference projects with international clients. Prospective partners should maintain organized digital certification archives with complete personnel qualification records, creating transparency and ensuring candidate claims align with actual capabilities for European projects.

Service Levels & KPIs to Contract

Establishing clear key performance indicators creates accountability throughout the recruitment and deployment process. Essential metrics include time-to-deploy benchmarks (typically 30-60 days), first-pass weld acceptance rates (industry-standard ±95%), and retention guarantees (often 90-180 days). Reputable partners offer performance warranties covering skill remediation or replacement when personnel fail to demonstrate certified capabilities, with clearly defined escalation protocols for issue resolution.

Hop Luc Global JSC’s Role

Hop Luc Global JSC exemplifies the comprehensive service model European employers should seek when pursuing pipe fitter recruitment Vietnam. Our approach encompasses rigorous candidate screening using European-standard assessment protocols, complete documentation management for visa and compliance requirements, and ongoing on-site support throughout assignment durations. We maintain digital certification archives with complete personnel qualification records and performance history, ensuring transparency and alignment with client expectations.

For detailed information on the complete workflow, consult our comprehensive step-by-step hiring process from Vietnam.

How to brief your project for successful pipe fitter recruitment Vietnam

Technical Brief: Materials, Classes, Tolerances

Providing comprehensive technical specifications enables optimal candidate matching and assessment preparation. Essential project information should include detailed pipe class specifications, material types (carbon steel, stainless steel, alloys), wall thickness ranges, flange pressure ratings, and applicable dimensional tolerances. Including information on specific welding procedures, non-destructive testing requirements, and acceptance criteria helps recruitment partners design appropriate assessment protocols that accurately reflect your project’s technical challenges.

Execution Plan: Shift Pattern, Supervision, Language

Clear operational parameters significantly enhance team integration and productivity. Defining shift patterns, overtime expectations, and reporting structures establishes clear workplace expectations. Specifying language requirements for technical communications and safety briefings enables appropriate language preparation. The provision of bilingual supervision, particularly during initial project phases, ensures clear instruction and feedback, accelerating the productivity ramp-up period for newly arrived teams.

Site-Readiness Checklist

Preparing worksites for incoming teams demonstrates organizational commitment and accelerates productivity. Essential preparations include provisioning appropriate personal protective equipment, arranging necessary specialized tooling, and ensuring proper lifting and scaffolding access. Establishing clear storage areas for materials and components, along with providing job safety analysis templates, creates the foundation for safe, efficient operations from the first day of deployment.

Strategic pipe fitter recruitment Vietnam represents more than staffing—it’s a competitive advantage delivering certified skills, compliance assurance, and predictable deployment that European industrial projects require. By selecting partners with demonstrated capabilities and providing clear project requirements, European employers transform labor challenges into operational strengths.

If your site needs steady throughput rather than short bursts, look for a partner that treats manpower like an engineered product. With pipe fitter recruitment Vietnam, you gain certified craft, predictable deployment, and a documentation trail your auditors can trust. Share your P&IDs, pipe classes, and timeline—we’ll map testing and supervision to your workfronts for a practical, low-risk start.

Ready to address your specialized piping needs? Share your P&IDs, WPS requirements, and project timeline for a detailed 7–10 day shortlist proposal. Discover how our comprehensive approach to pipe fitter recruitment Vietnam can solve your skilled labor challenges.

-

Hotline: +84 983 688 060

-

Email: contact@hoplucglobal.com

-

WhatsApp: +84 983 688 060

For complete context and procedural details, explore our complete Vietnam–EU recruitment guide.